free shipping on orders over £100

free shipping on orders over £100

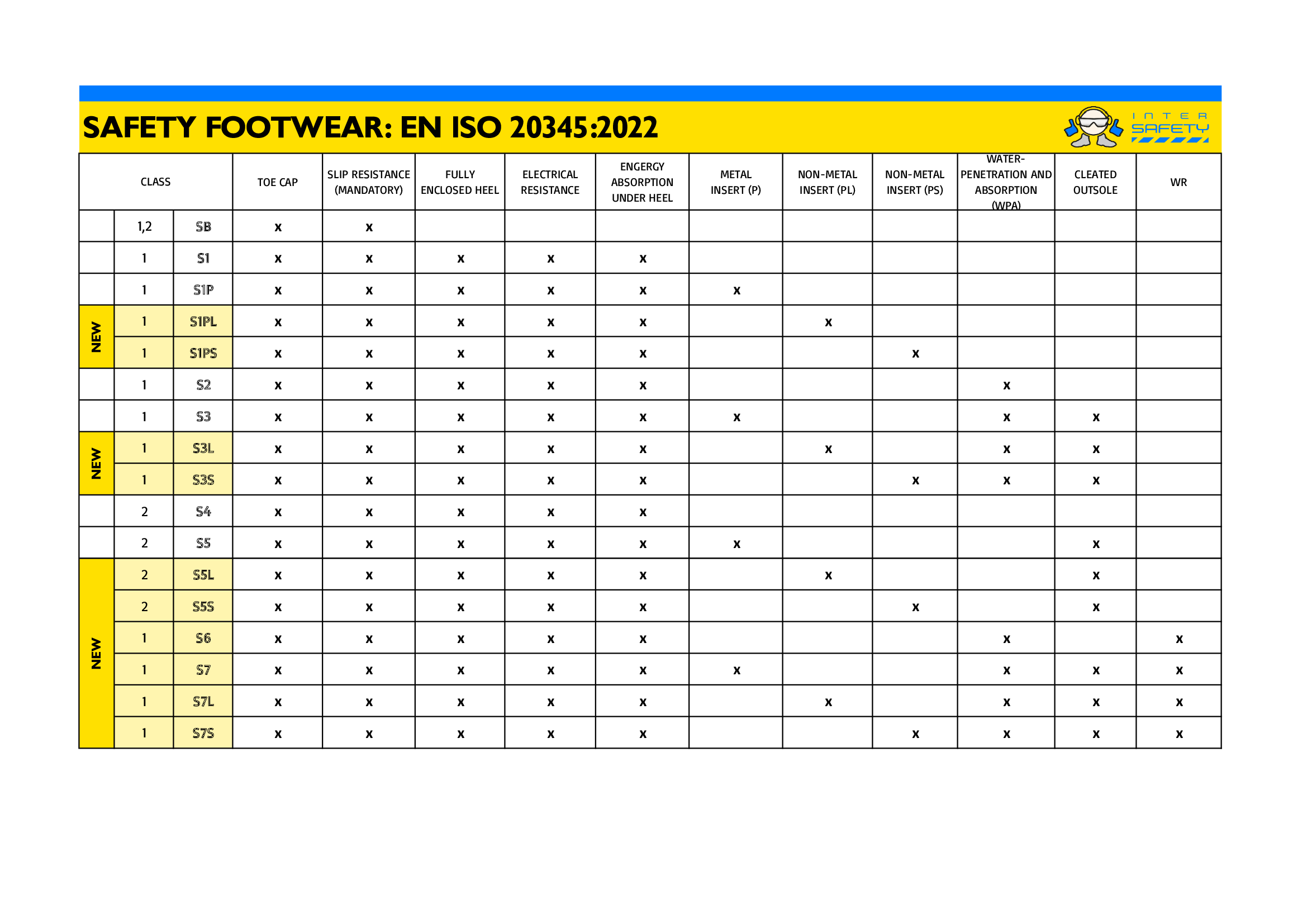

The new version of regulations for safety footwear has recently been published, with a host of updates from slip resistance through to ladder grips. Working closely with our suppliers, we’ve compiled these changes into a more digestible guide to ensure you have the right safety footwear for the job. Read on…

1.SLIP RESISTANCE

As with many areas of PPE, the highest rating is too often considered the best for ALL environments – when this is not the case. For example, a slip resistance classification of SRC was perceived as the optimum option when design principles to achieve good SRA or SRB results had to be compromised to reach a best of both.

SRA, SRB and SRC have now been scrapped. Instead, slip resistance (SR) will be a mandatory requirement and will therefore have no marking. The standard test will be similar the current SRA system, conducted on floor tiles with a sodium lauryl sulphate (soap) solution.

Certain footwear types, such as those with specialist features or spikes, may be exempt from slip testing and will display the marking “Ø”.

2.NEW PROTECTION LEVELS: S6 and S7

Put simply, S6 ratings will replace the existing S2WR (S2 with waterproofing) and S7 ratings will replace the existing S3WR (S3 with waterproofing).

S6 and S7 footwear must be made of water-resistant materials on the upper and be fully water-resistant. This was previously known as WRU (water-resistant upper) and will now be referred to as WPA (water penetration and absorption).

3.PERFORATION RESISTANCE (NON-METALLIC INSERTS)

The previous standard gave a marking of ‘P’ to indicate a pass in puncture resistance. The revisions have added two more: PL and PS. These indicate the size of nail used – the smaller the nail, the higher the pressure and the higher the requirements for protection.

P: Nail protection with a steel insert, tested with a nail of 4.5mm diameter.

PL: Nail protection with a non-metal insert, tested with a nail of 4.5mm diameter.

PS: Nail protection with a non-metal insert, tested with a nail of 3mm diameter.

Where the risk of encountering sharp objects less than 3mm is high, a steel insert is recommended.

A protection level of S1 with perforation resistance will still be displayed as S1P, as before. However, the new subgroups have been incorporated as S1PL and S1PS. Where the protection level already includes a requirement for perforation resistance, the marking simply specifies the type of protection, i.e. S3, S3L or S3S.

4.Ladder Grip Test

This indicates suitability for ladder use and was typically intended for firefighters. This has now been copied to a standalone test for all safety footwear, although it is not a mandatory requirement. The test is focused on the area between the heel and forepart of the boot below the arch and will display an ‘LG’ marking if passed.

5.Scuff Cap Test

Scuff caps are now subject to a durability test. They must surpass 1000 abrasion cycles in order to pass and display an ‘SC’ marking.

6.Fuel Oil Resistance: no longer mandatory

Resistance to hydrocarbons has become an optional requirement and will now be an additional test on footwear intended for environments with fuel and oil.

Safety footwear placed on the market after 30th March 2023 must be certified in accordance with EN ISO 20345:2022. However, any existing products do not need to re-certified until its certificate reaches its expiry date. As a result, we will see a mix of new and old standards across the market for the time being.

If you have any questions or product enquiries relating to the above information, feel free to contact the team at Intersafety using the contact form below. We’ll get back to you as soon as we can!

Sign up to our mailing list and keep up to date with all the latest products, deals and discounts!

This company undertakes to supply only safety equipment and/or related services that fully comply with the standards and regulations and claims made relating to those products and/or related services. Where appropriate, this company will maintain up to date technical files and associated documentation to ensure that regulatory compliance information can be supplied upon request.

Where products are sourced from external organisations which hold technical files relating to the products being offered, this company will request confirmation that these files are current, complete, contain appropriate conformity assessment information and, where relevant, regulatory compliance certificates and will take all necessary steps to confirm the validity of the compliance documentation held by that external supplier in respect of the products being sourced.

Where services are provided related to safety equipment sourced from external organisations, this company will maintain approval from the manufacturer that the services provided are assessed and approved by the external organisation.